Everything you need to know about cultivating microalgae

October 13, 2020

With no competition for land, faster reproduction cycles than most plants, numerous co-product possibilities and a positive environmental impact, microalgae cultivation is generating interest across a multitude of markets. But for each application, it is important to choose the right technique and technology.

Let’s take a look at the different microalgae culturing methods.

Microalgae were one of the first living organisms on earth. Although some – like Spirulina and Nostoc – have been harvested for many centuries, cultivation and extraction techniques were only developed from the middle of the 20th century. Since, then, the range of applications continues to grow:

- Nutrition and phytopharmacy

- Cosmetics

- Agriculture

- Energy

- Depollution

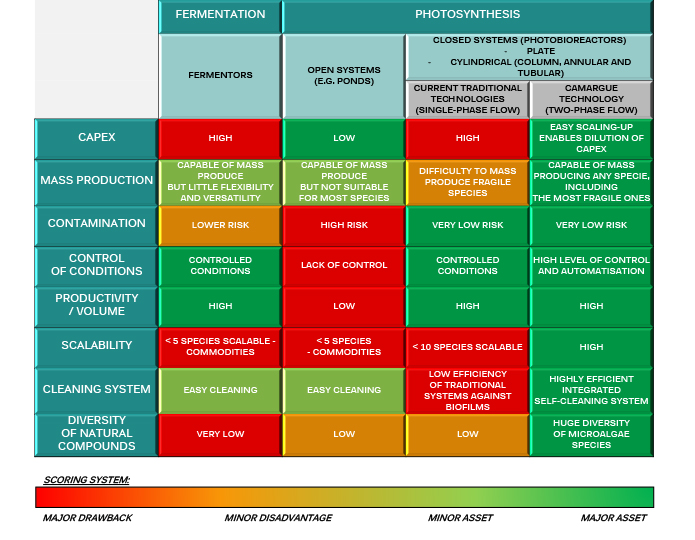

To culture microalgae and extract their active ingredients at an industrial scale, today there are three types of technology developed progressively over the last 50 years: open systems (Open ponds/Raceway), fermentors and photobioreactors.

Pioneering microalgae cultivation: open systems

In France, microalgae cultivation began in the late 1970s with open-air systems using discontinuous basins and semi-controlled conditions. Over the years, these culturing systems have been perfected. Among the most widely used are raceway flow-through systems with their distinctive racing-track format. Easy to manage with limited investment costs, these open systems can be used to cultivate only the most robust (even extremophile) microalgae like Spirulina. The microalgae are exposed to climatic variation and the risk of contamination e.g. predators, bacteria and other microalgae. These constraints make open systems the least productive method in terms of microalgal diversity – see table.

Fermenters for specific products

Microalgae can also be cultured in a completely closed fermenter system. With no light source, the microalgae stop photosynthesizing but still breathe using sugar as a source of energy. This technique requires strict sterile conditions. As this technique deprives microalgae of light, it can only be used for certain varieties and therefore for a limited range of products. The advantages? High volume-based productivity and low production costs. In recent years, mixed processes have been developed in an attempt to combine the advantages of autotrophic and heterotrophic systems.

Photobioreactors, inspired by nature

In 1957, at MIT (Massachusetts Institute of Technology, USA), the first photobioreactor (PBR) was developed. As a closed system, the photobioreactor recreates an optimal biotope for microalgae, which are stimulated using a natural or artificial light source. The vertical or horizontal tubes are transparent meaning that photosynthesis can usually occur (autotrophic system). The growing conditions are controlled – nutrients are added, and the temperature, pH and dissolved oxygen monitored. The microalgae therefore grow in an environment very similar to their natural habitat.

Camargue: innovative photobioreactors

In 2009, Microphyt developed and patented a unique, biomimetic process baptized Camargue, which tackles the main challenges of cultivating fragile microalgae at an industrial scale using photosynthesis. Currently, the 20 tubular 5000-liter photobioreactors covering 55 m and standing at 3.8m offer:

- A wider field for microalgal investigation than other industry players

- Quality and traceability with a closed environment controlled at every step

- High, multi-product production capacity

- A process that respects the environment

Beyond technical, performance and financial considerations, the choice of microalgae cultivation method also depends on the characteristics of the different microalgae varieties and their valorization. Not to mention the environmental impact.

For more information on Camargue photobioreactor technology, click here.